Building on the successes of the “Augmented Learning for High Dexterity Manufacturing – LayupRITE” project, follow-on funding was acquired from the Ufi Voc Tech Trust. This projected, “LayupRITE 101” sought to integrate the LayupRITE methodology into an existing composites training course. Due to the LayupRITE technology being originally focussed on manual layup the “Introduction to Manual Prepreg” course run by NCC Connect was selected as a template.

Intro to Manual Prepreg and LayupRITE

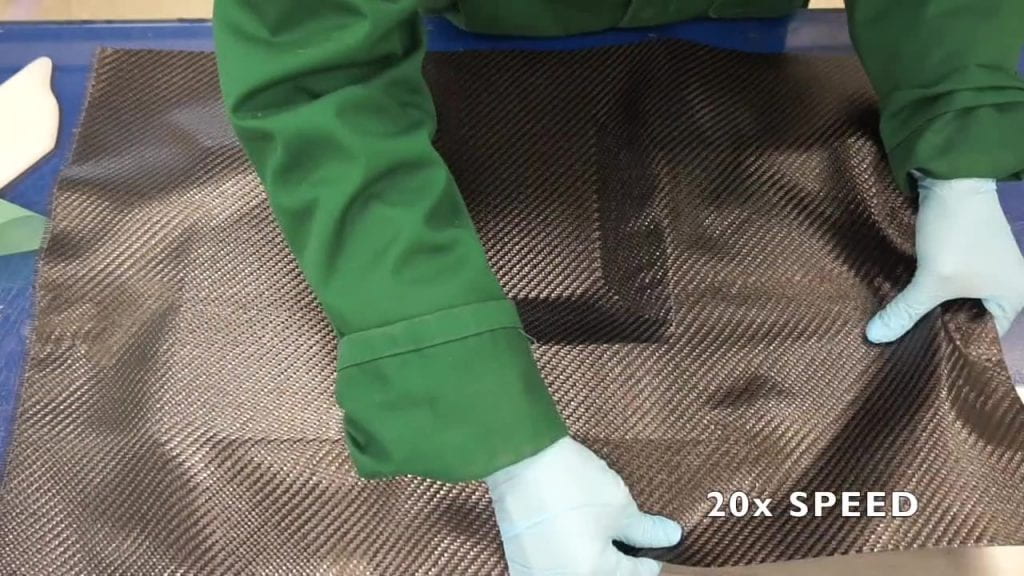

This course, as the title suggests, is an introduction to the techniques and theory of laying up a component using prepreg materials. Currently the course is run over two days and split into four sessions. Two of the sessions are classroom-based theory, the other two are workshop sessions to teach the hands-on, practical skills of working with prepreg materials. It was felt that this course, both the theory and practical aspects, could be effectively digitised. The classroom content could be delivered using e-learning techniques and the workshop activities could be assisted with LayupRITE.

Benefits of LayupRITE

The aim of integrating e-learning and LayupRITE into this training course is to augment the trainer and move toward a more “blended learning” experience for the learners. This would expand the reach of the training to more learners and give trainers the opportunity to do fewer demonstrations and spend more time supervising and guiding.

The other opportunity is to use simulations to allow students to learn composite drape in a lower-risk way. Simulations would let users try unlimited approaches to a layup task without the cost or risk of handling prepreg materials. Additionally, digital simulations don’t require a workshop and so can be done anywhere, any time.

Tacit skills and workshop tasks

However, the tacit, hands-on skills developed during the workshop sessions are a crucial benefit of the course. These skills can’t be effectively replicated digitally, but use of digital tools, such as augmented reality and simulation practice, can be used to focus the workshop tasks toward getting the necessary skills.

Using digitally delivered simulations to the learners mean that they will have an on-hand reference to the task. For the instructors it will lead to less time giving general demonstrations and facilitating more individual guidance. To make this an enhancement rather than a burden, LayupRITE will have to have be simple to set up and provide enough information at the right level for the user. The previous LayupRITE project has given the team insight in how to achieve this.