This series of posts is intended to showcase the top-level outcomes of Ufi Project 1 titled “Augmented Learning for High Dexterity Manufacture”. This project was funded by Ufi, a vocational learning charity. The main difference between this and previous works was that the focus was on skills training. Training had always been touted as an application for LayupRITE, but this was the first time it was the specific goal. This gave the project two opportunities: firstly, to further develop the LayupRITE system and secondly to get a closer look at training as an application.

Skills training and Horizon Scanning

A key difference in was required when thinking about skills training. Previously, our strong suit had been in drape simulation and working toward making unambiguous instruction sets. Going into this project we believed that we could make a series of moulds of increasing complexity and walk the learners through. However, it was explained to us that that wouldn’t necessarily do any thing for the retention of the information. This was the best explanation we were able to come up with:

IKEA do great instructions, but if you were to take those instructions away, would you be able to assemble that wardrobe tomorrow, or next week? Would you know how to assemble a similar, but different wardrobe?

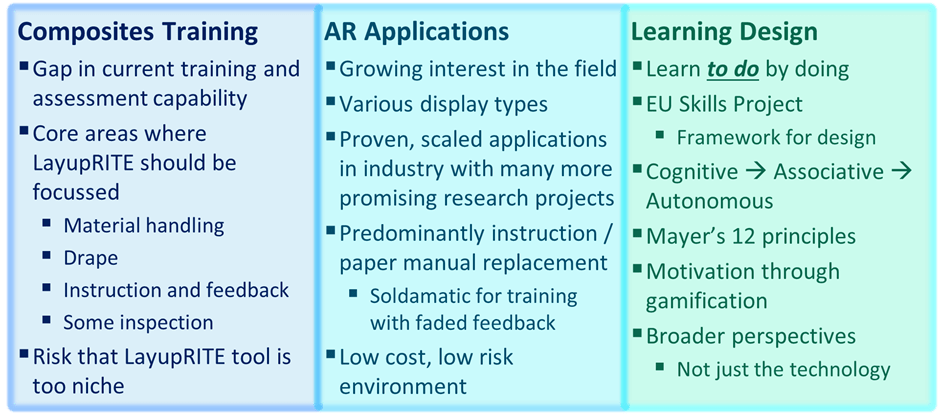

We also had to understand what good looked like from a learning design standpoint and what was out there already. To achieve this, we undertook a “Horizon Scan” of the current landscape of skills training in composites, current augmented reality (AR) applications and a study of learning theory and instructional design. The top-level outcomes from these three pillars were:

The composites training and AR applications pillars gave us encouragement that there was a space for LayupRITE to exist. There were a variety of AR applications in other industries and there appeared to be an opportunity to modernise, digitise and “smart”-ise composite laminator training.

A particularly interesting application was Soldamatic. Their system uses a welding visor/headset and torches with AR markers to better simulate the working environment. The system displays the material type overlaid onto real-world models of components to be welded. What is of interest here is how it ties in with the learning design findings, particularly “fading feedback” and “Cognitive – Associative – Autonomous”. During the course of the Soldamatic system the heads-up display in the visor displays less and less information as the user gets more experienced. This is a great example of “fading feedback” and ties in with the “Cognitive – Associative – Autonomous” approach to learning.

The Cognitive – Associative – Autonomous Model

- Cognitive – The learner is being told what to do and must think about how to do the task

- Associative – The learner understands what to do and can predict outcomes

- Autonomous – The task is performed instinctively, the focus is on strategy and efficiency

7 Principles for “What good looks like”

Finally, the pillars of the Horizon Scan led us to 7 principles for what good looks like:

1. Learning outcomes and performance standards to be achieved are clearly defined

- the precise and detailed analysis of the skills and processes, and the range and degree of difficulty of these to be covered

- the accuracy, speed and consistency with which they need to be undertaken

- the expected capability to transfer and adapt their application to different circumstances

2. The learning programme takes account of the stages of skills acquisition and the level of expertise of the learner

- starting with prescriptive guidance of generic skills, moving toward the information received in a manufacturing context

- fading feedback as learner moves through programme (and transitions through skills acquisition stages)

- self-direction and autonomy of learning programme (will need trainer intervention/assessment as well)

3. A low risk, low-cost environment provides for relevant and deliberate practice

- low risk – training environment lower risk than in-house training on real parts

- low cost – attempt to simulate material (material is largest cost in training), lower cost than taking experienced staff away from production, aim to accelerate skill acquisition

- deliberate practice – user control of programme

4. Guidance and feedback is targeted on what the learner needs to accelerate their skills acquisition and presented as simply as possible

- “as realistic as necessary” – animations preferred over video

- “multi-modal” – explore options for audio as well as visual feedback

- multi-screen – use of secondary display for more detailed/ancillary information

5. The learning programme enhances and supplements, if necessary, the intrinsic motivation of adult learners

- evidence of competence displayed to the learner (some gamification) – mastery

- show where these skills are used (e.g., high performance auto/aero parts) – esteem/recognition

- user-control over learning programme – autonomy

6. Evaluation is built-in from the outset and enables continuous iteration and improvement

- Relevance – relevant evidence provided

- Facilitation – development of effective accelerators

- Transferability – does the training transfer into the real world?

7. Attention is given to the whole learning context, not just the technology

- Practical issues – how the tool is set up and used

- Learner perspectives – introduction to tool at different levels of experience etc.

- Trainers and coaches – roles, support learners, how the tool supports them

- Wider environment – employers, awarding bodies, product design, quality control etc.